Problem statement

During the reconstruction of a parking garage in Lidingö, Sweden, where the roof structure was planned to be used as a green terrace, both the need to reinforce the structure and concerns about visible cracks in the column brackets were raised. Reinforcement measures in the form of carbon fiber reinforced plastic (CFRP) wraps and steel angles as well as external prestressing had already been installed for the transversely prestressed beams, but an independent review was required to ensure that the work was carried out correctly and that the structure was safe for future loads. At the same time, a deeper technical analysis of the cause of the cracking of the column brackets was needed, as these form a central part of the structure and their long-term functioning is crucial for the stability of the whole building.

Outcome

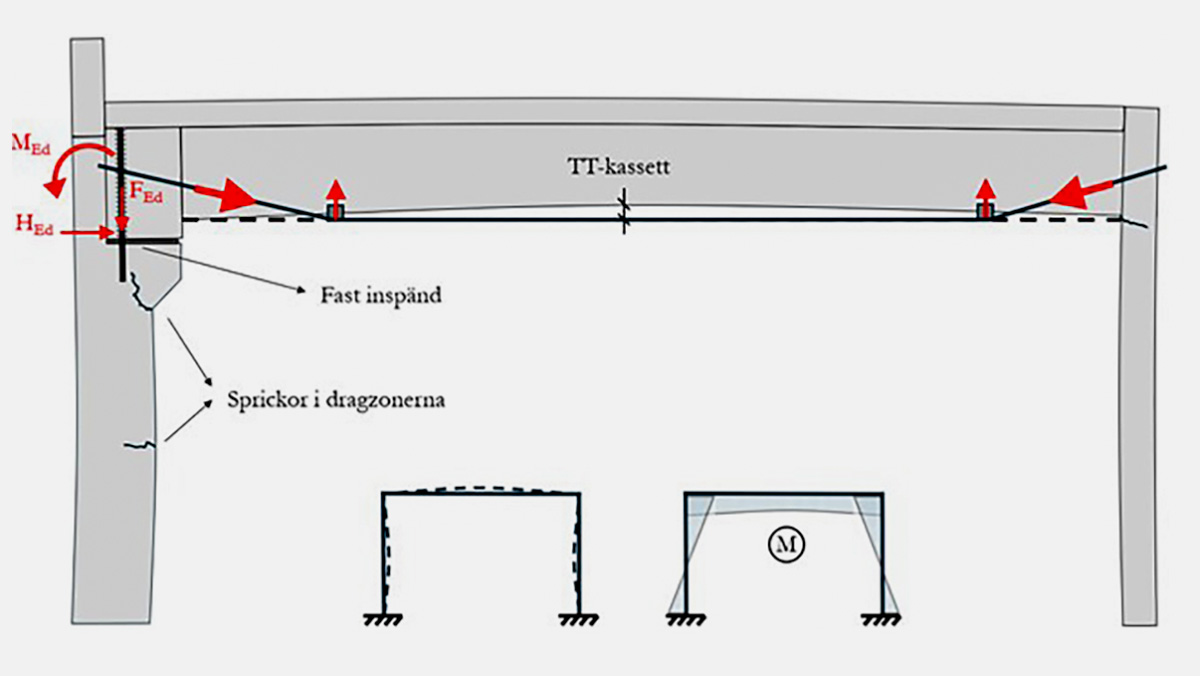

Our inspection and analysis showed that the strengthening measures had been carried out correctly and met technical requirements. Through the combination of visual inspection, thermography, GPR and ultrasound, we found that the carbon fiber wraps and steel angles were well anchored and had good adhesion, with only minor deficiencies that did not affect the function. Furthermore, the condition assessment of the column brackets showed that the cracks were mainly due to the external tension cables causing rotation in the beams, transferring moments to the columns. These cracks were small (≤0.3 mm) and below the limits set by EKS 12. Our analysis also showed that the main reinforcement was sufficient to withstand the applied loads, although the detailed design could have been better. Overall, we were able to give the client a clear conclusion: the structure is safe and no further strengthening measures were required.

Solution

To reach this conclusion, we worked step by step and methodically. First, we carried out a check of the reinforcement measures carried out, using advanced measurement methods such as thermography and GPR, as well as ultrasound to detect any deficiencies. This was followed by a detailed condition assessment of the column brackets, combining several types of testing:

- Visual inspection and crack measurement to document the location and width of cracks.

- Non-destructive testing such as GPR scanning to map reinforcement, UPV to analyze the quality of the concrete, UPE to identify voids, and the Schmid hammer and SONREB method to estimate compressive strength.

- Destructive testing by drilling and exposing the reinforcement, giving accurate values for the cover layer, reinforcement diameter and carbonation depth.

- Geometric measurements with laser to analyze bearing surfaces and rotations in beams.

- Finally, Eurocode calculations were carried out, comparing different load scenarios (previous with sedum roof and snow, current with post-tensioning). These calculations showed that the structure is robust and that the cracks will not develop further.

By combining practical testing and advanced calculation models, we were able to provide an overall assessment that gave the client confidence.

Equipment

- Thermographic camera for the control of carbon fiber reinforcements

- Hammer for sound control

- GPR scanner (Proceq GP8000)

- UPV instrument (Proceq Pundit PL-200)

- UPE for cavity analysis and thickness measurement

- Schmid hammer for estimation of compressive strength

- SONREB method (combined UPV and Schmidthammer)

- Drilling and chiseling equipment for exposing reinforcement

- Crack width meters and laser meters

- Equipment for carbonation testing

Standards

- EN 1990: Eurocode – Basic design rules

- EN 1991-1-1: Eurocode 1 – General loads

- EN 1991-1-3: Eurocode 1 – Snow load

- EN 1991-1-4: Eurocode 1 – Wind load

- EN 1992-1-1: Eurocode 2 – Design of concrete structures

- EKS 12: Boverket’s construction rules

- Mosley, Bungey & Hulse (2012). Reinforced Concrete Design to Eurocode 2