Problem statement

Damage to existing tension cables in concrete structures, especially rough structures, is extremely complicated to survey if one is not allowed to open up the concrete and the casing to the tension cables. In this case, several sections of a bridge in western Norway were surveyed. The client was concerned that the cement grouting was substandard and that the tension cables had started to corrode. This assumption was based on previous mapping by destructive sampling. If the survey revealed extensive grouting deficiencies, it would have to be either repaired/reinforced or replaced at a cost of approximately NK 300-400 million.

Solution

The task here was to identify defects in the tensioning system of an existing concrete bridge. We have developed a methodology that has proven to be successful. In principle, the mapping is carried out in the following steps.

Existing documentation

Overall mapping of the site.

Focus on critical sections.

GPR (Ground penetrating radar)

Using electromagnetic pulses and their reflection to map the location of reinforcement and casing.

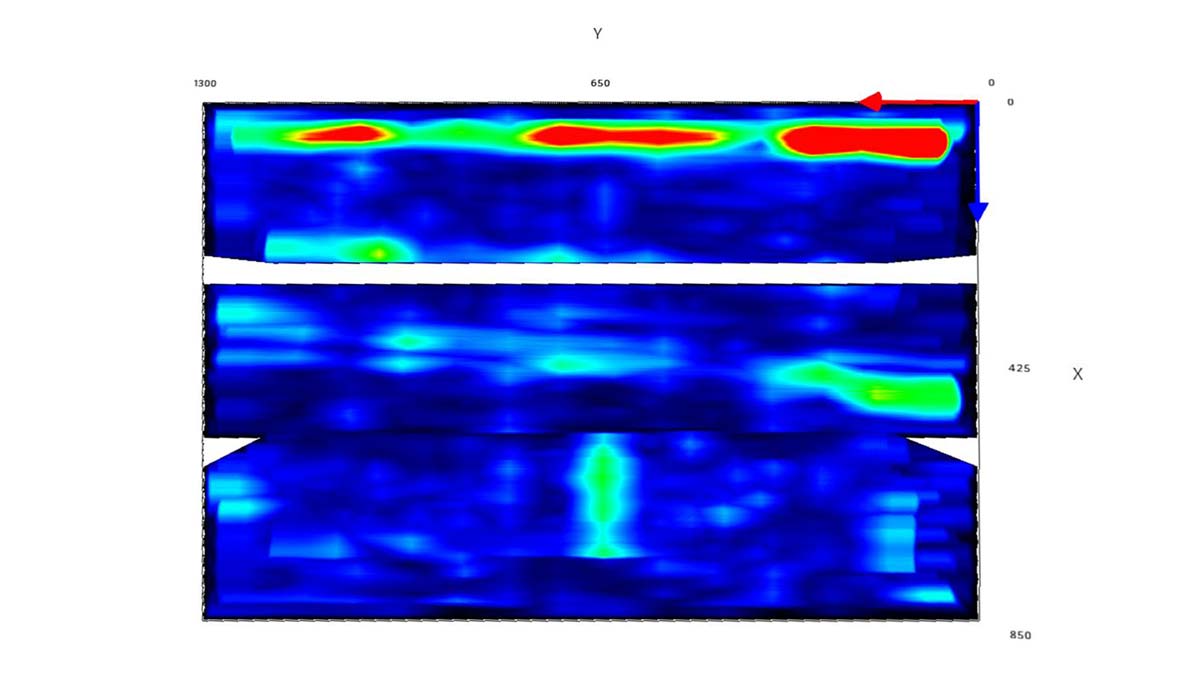

Ultrasound (Tomography)

By sending S-waves (Shear Waves) into the structure through direct contact with the equipment, information about cavities in the casing can be obtained – strong signal. Without cavities, the signal goes through the casing and the signal is weak.

Impact echo

Once any cavity has been mapped using ultrasound, the examination is refined using impact echo. This gives a more detailed picture of the injury.

Verification

Partial exposure of the tension cable by drilling through concrete and into the casing. We then use an endoscope to map the cavity as well as corrosion and breaks in the cables.

Standard

Modified ISO 16311-2 and ISO 138 22.

Commentary

The project was very successful. Despite difficult weather conditions and extensive need for investigation, this work could be carried out with 3 people for about 10 days including report writing and compilation. We have simply succeeded in developing a methodology that can map defects in prestressed concrete structures in a good way.