Problem statement

Invator Sverige AB was commissioned by SWECO to carry out a special inspection of the tension cables on Vallbybron in Västerås. The purpose of this inspection was to investigate the condition of the tension cables. There was leakage via leaky manholes placed in the bridge deck and a large amount of chlorides had been found around the slack reinforcement, which created doubts about the status of the tension cables.

Outcome

With non-destructive testing, we were able to rule out substandard grouting in the tension cables, however, there were chloride levels near and above critical levels but no corrosion in the cables. With our solution, the Swedish Transport Administration got a good basis for future action plans and the knowledge that there was no critical damage to the tension cables that could pose a danger to the bridge.

Solution

- Review of previous materials and drawings in order to draw up an inspection plan.

- Locating and marking the extent of tension cables using GPR.

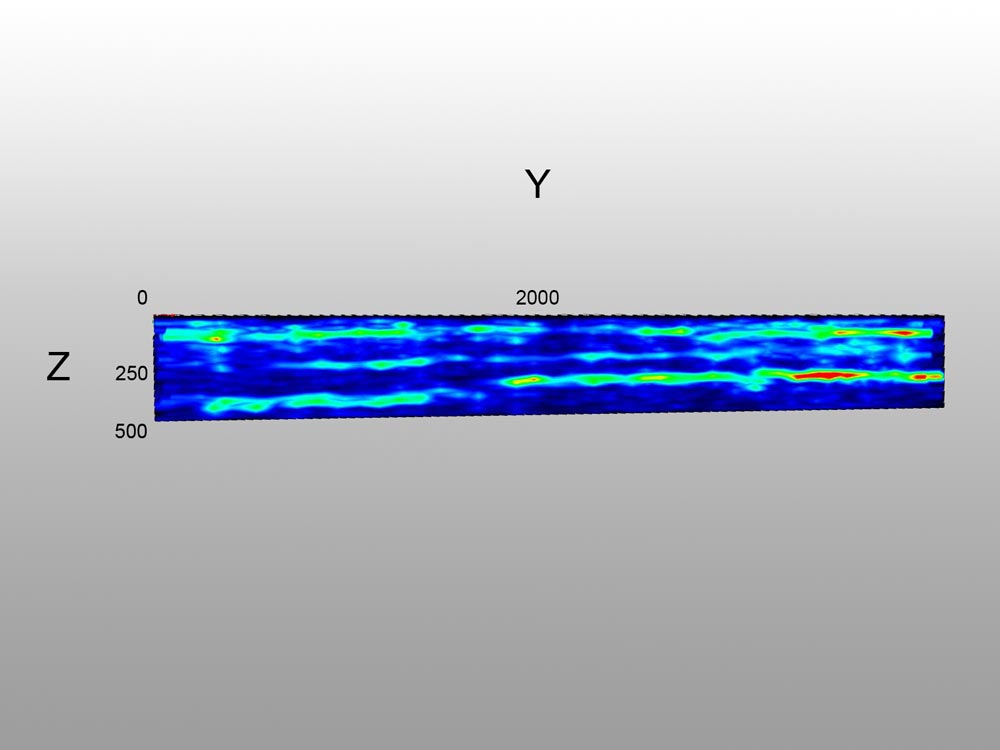

- Control of cavities in feed tubes by ultrasound.

- Verification by core drilling into casing.

- Opening of casing and sampling of grout.

- Repointing of boreholes with repair mortar according to own approved procedure.

- Control of chloride content in grout in own laboratory with RCT.

Equipment

- Cover gauge: To calibrate GPR and locate slack reinforcement.

- GPR: used to locate the tension cables.

- Ultrasound (MIRA): The main equipment for the inspection, locates cavities inside the feed tubes.

- Videoscopes: Used to enter and take pictures in the lining pipes and to examine any corrosion on the tensioning wires more closely.

- Core drill: to be able to open up to the casing and inspect the tensioning reinforcement.

RCT: Rapid Chloride Test is used in our lab to analyze the chloride content in the grout.