Problem statement

During repair work on the bridge in 2019, major damage and corrosion were found on a tension cable. A random inspection of the tension cables was carried out in 2020, which showed that the damage situation was more widespread than feared. It was decided that the bridge would be demolished and a new bridge built. This led to a major research project to map the extent of damage in detail. Invator AB was entrusted to carry out the non-destructive testing on the bridge to identify voids and corrosion in all casings in 2023.

Outcome

Our inspection mapped all the cables and found several serious damages to the tension wires including cable breaks. In total, nearly 270 m of tension cables were scanned on the bridge. The work we carried out on this bridge forms the basis for how Vegvesendet will carry out its inspections of the tension cables in the future and they are drawing up an inspection manual based on our methods.

Solution

To be able to handle such a large number of scans and to be able to follow up exactly where we might find voids, we started by drawing the entire bridge in CAD, with the dimensions we wanted.

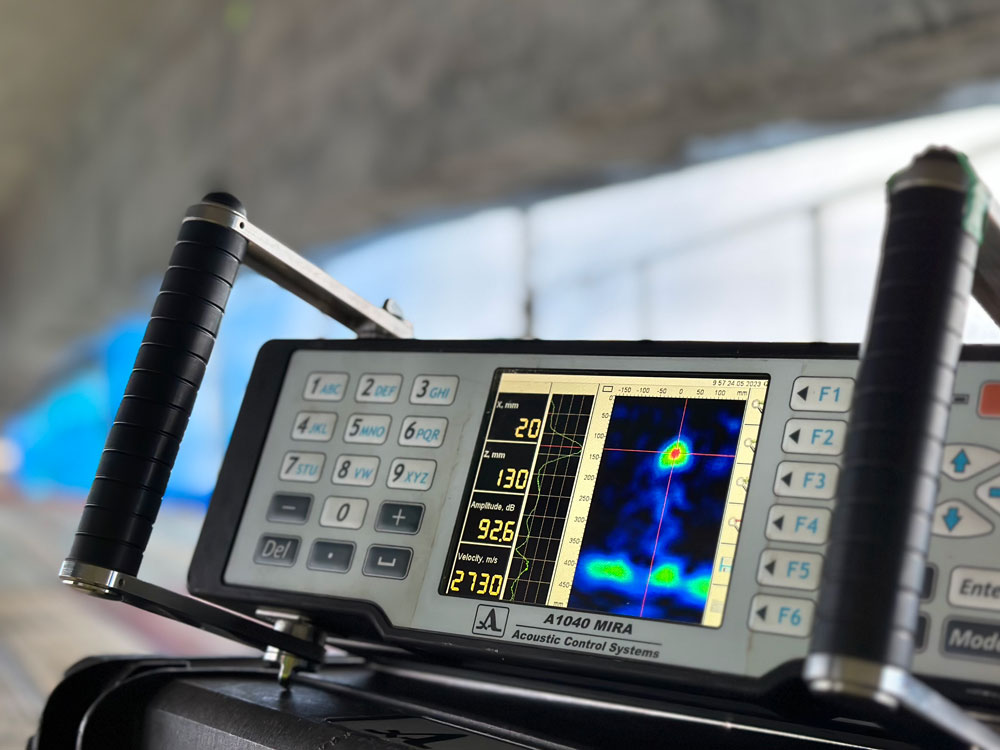

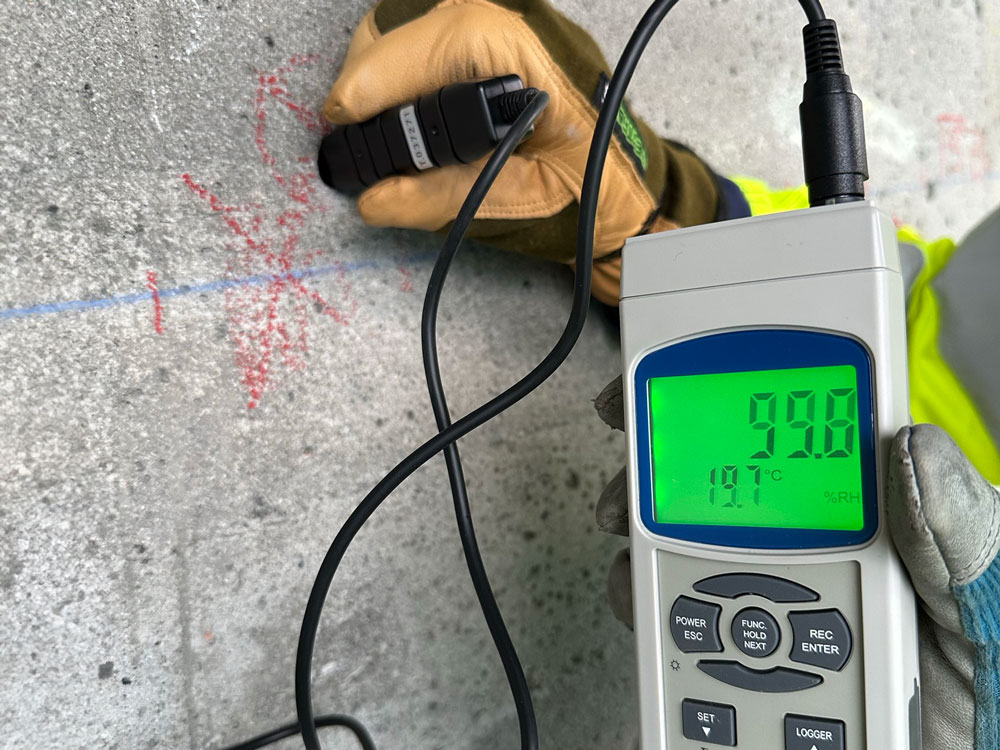

Once on site, we were able to locate the tension cables with GPR and mark them out on the bridge with the names and dimensions we had specified in the drawings. Work then began on mapping the cavities using ultrasound, which is a time-consuming process. After the scans were completed and the results analyzed, we carried out a number of verifications with core drilling. We also sampled the grout and carried out moisture measurements inside the empty cable ducts immediately after opening.

Equipment

- Coating thickness gauges

- GPR

- Ultrasound (MIRA)

- Impact echo

- Videoscope

- Moisture meter

- Core drilling equipment